The North Conveyor Mk2B Roadheader at 194m in 1985.

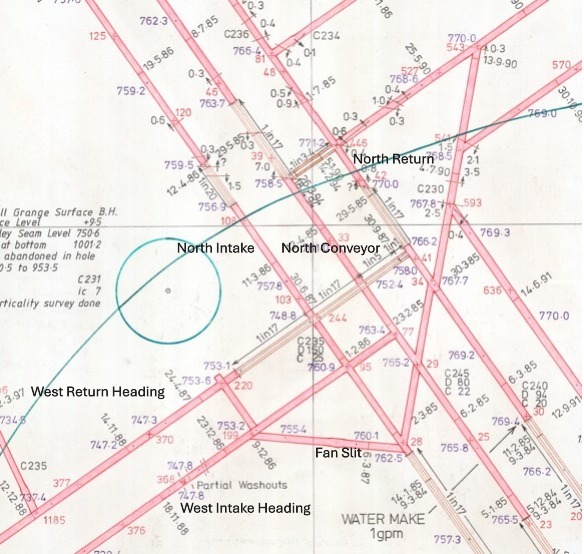

When the North Conveyor heading had progressed 700m in Feb 1985 a large junction was created. The Mk2B roadheader then continued on to the north of the mine. At the same 700m point in the North Intake heading in Feb 1986, a junction was created and the cross slit was created between the North Conveyor and North Intake roadways. At the North Intake junction, an heading was started, to develop the coal at the west of the mine. When the heading had progressed 100m a further junction was created. The machine turned right to create a 70 metre cross slit for the West Return and West Intake stub headings. The machine then drove an heading back towards the North Intake at 45° to create a ventilation slit for the heading fans and loco access. This development was phase two of Riccall Mine, to access the coal at the west of the mine up to the boundary with Wistow Mine.

In October 1986, the North Return and North Conveyor lateral roadways were completed. The South Conveyor was completed and the Return was well advanced. Both North and South Intakes were half completed and face developments were also started on both sides of the mine. This was the first phase of the development of the mine.

The West Development Headings.

In Nov 1988 the west development headings were started by mining contractors, Thyssens. The machines used for the West Conveyor heading was a Dosco Mk2B roadheader and West Return headings was a Dosco MK2A revised hydraulics roadheader. The headings were supplied by two Becorit battery locos owned by Thyssens. These locos moved equipment from a transhipment point at the bottom of the West Conveyor roadway.

Before the West Return lateral heading started, the West Return connection roadway, to the North Return, had to be completed. It was a 1 in 17 drift changing to a 1 in 5, driving above the North Intake and North Conveyor roadways. The connection, a 1 in 1 Drift, was created upwards from the North Return, using bore and fire with a slusher to muck out, to complete the heading. This drift was called Zolly’s Drift after the Thyssens general foreman. This allowed the West Return air to travel to the upcast No2 shaft.

The West lateral headings progressed and made junctions for H471s and H472s faces. The West faces were to be taken off the West Return retreating in a north to south direction. The first face to be developed was H472s. These headings were driven by Thyssens using Lee Norse LN800 2.5tt continuous miners and were supported using arch girders.

H472 Face and South West Trunk.

H472s face development gates were started in March 1990 and the 700m face headings, including 230m faceline, were completed in Oct 1990.

The cross slit between the West Return and Conveyor Road was completed and the west side 6.6kv ring main MIVAC substation was built in the slit, at a later date, to supply all the 8 west faces and and headings. A roadway was taken off the West Conveyor called the South West Trunk.

H472s coal face was the first one at Riccall Mine to have a Joy shearer. The first Joy shearer used in the country was at Manton Colliery on 39s face. It was a 3LS and proved very successful. At the time H472 was to be installed, 2 shearers were made available for Riccall Mine. A Joy 4LS and the ex Manton Colliery, Joy 3LS. It was decided that Riccall Mine had the Joy 3LS and Trentham Colliery got a new Joy 4LS. The 485kw, 3LS installed at Manton Colliery and then Riccall Mine, was the only one ever used in the U.K. and is now on display at the National Coal Mining Museum.

Joy 3LS Shearer cutters

The Joy 3LS was a brilliant coal cutter. It was a very powerful multi motor shearer capable of unbelievable cutting speeds. The combined horsepower of the machine was over 600 horsepower with each of the two cutter motors rated at 250 horsepower. The hydraulic onboard pump, and the D.C. traction haulage motors were a combined rating of 100 horsepower. The hydraulic pump was used purely for moving the ranger arm rams.

The 2×35 Horsepower D.C. traction motors were thyristor controlled with speed control set using a programmable electronic module. The traction drives operated a gear which sat on a huge captivated chain to haul the shearer through the face. We were told that when used in the American mines, where the face workers didn’t work on the tailgate (dusty) side of the shearer, the machine could cut at 60 feet per minute. We had stricter dust regulations in the UK so these speeds were restricted. The shearer driver operated the machine using a remote control powered from his lamp battery via a lead.

The machine had a control section with an LED diagnostic panel situated in the middle section which was useful for fault finding. The cutter drums on the shearer was so designed that if it struck a solid object such as a chock beam, the output shaft from the ranger arm, to the cutter, sheared to ensure no damage to the gears of the ranger arm occurred. It was called a quill shaft.

H472s face was developed, as mentioned earlier, using Lee Norse continuous miners using arch supports. It was ready to start production in Jan 1991. The main gate pantechnicon was rail mounted and the face equipment was Gullick Dobson transferred from the northside of the mine. The face was very successful, finishing production in June 1991.

H472s face team with methane borers.

All faces at Riccall Mine had the entire electrical equipment, including transformers, returned to the surface, on every face, for a complete overhaul, redesign and testing. As the electrical equipment evolved, due to electrical developments, plug and socket connections were fitted, where allowed, for ease of salvage and installation.

West side faces from H470s

West side faces from H472s showing South West Trunk development.

West side faces from H474s H477S.

Lee Norse LN 800 continuous miners were used for all the West Side face headings with high rates of developments achieved due to the seam section becoming thicker as the mine progressed westward and the introduction of total bolting as the primary support system. The last 3 faces at the west of the mine were supplied with face equipment from the newly formed mining company, Longwall International, a merger of Meco International and Dobson in Jan 1993.

As the West lateral developments progressed the conveyor system was changed due to the length of the drivages and the faces worked. The slit from the outbye end of the conveyor road to the steel cord had a Huwood double drive which delivered onto the steel cord conveyor. A further Huwood double drive was installed just inbye of H472s slit supplied by an Wallacetown H65 installed on a large purdy platform outbye of H472s.The platform had to be built with sufficient height to allow men to walk underneath so we built the switchgear on the platform and then lifted the entire platform as high as possible. The conveyor became a manrider except for a short section at H472s junction where the South West Trunk delivered on the West Conveyor.

The face taken from the inbye end of the West Return was H477s with a seam section over 3m and the chocks working on there limit. The equipment was then transferred to H478s which was a face developed on the West Side of the South West Trunk roadway. The next two faces taken off the West Return were H471s with 1000m gates and H470s with 550m gates. These faces used the equipment from H478s and were very successful faces both completed by Feb 1998.

Photo above shows the H471s face team in mid 1997. The lads shown are top row, left to right; Steve Priestley (Tiger), Andy Lister and Bob Yorke. Middle row, right to left; Ian Liptrot, Eddie Jordan and Steve Commons (Old hand). Front row, left to right; Roy Minett, Paul Morton (Pinky), Willie Baxter and Paul Ward. The photo has been kindly given to me by Ian Liptrot who has a copy from the RJB News magazine. It is taken at the main gate entry to the face.

The last two faces worked on the west side of Riccall Mine were developed from the West Conveyor roadway. These were very short faces to remove the final couple of blocks of coal at the west side of the mine. H434A’s development was started in September 1997. The Main Gate was driven with a Dosco MD1100, a 34 Tonne, 157 kw, medium sized roadheading machine.

Dosco MD1100 Roadheader.

West side H434A’s and H434B’s face plans.

H434A’s tail gate was driven along with the face line heading and then abandoned on 20 Feb 1998. In June 1999 the heading was de-gassed and development was restarted to complete the main gate roadway back towards the West Conveyor roadway. The heading was completed in September 1999. The face, which had 400m gates and a face length of 180m was installed and started production in January 2000 using a Joy 3LS Shearer with Joy face equipment and standard Wallacetown SIMOS 1100v electrical equipment. The face finished production in 12 weeks on 29th March 2000.

H434B’s started development on 20th Nov 2000. The face headings were completed in the same way as H434A’s in one complete development starting with tail gate, faceline then main gate using a Dosco MD1100 and was completed on 23rd May 2001. The equipment from H434A’s was installed and production started on 13th August 2001. The face was 200m long with 500m gate roads and took 3 month to complete production, finishing on 23rd Nov 2001. This was the very last face at the west side of Riccall Mine.

All the West faces had outstanding production figures, producing millions of tonnes due to the outstanding workforce, face conditions, seam section and Gullick Dobson / Longwall international face equipment, including the brilliant Joy 3LS shearer mentioned earlier, which was used on most of the West side faces from 1990 until 2001.

Many thanks to Ian Liptrot, who was an electrician at Riccall Mine, for information on H434s faces and the great photo of H471s team.

Many thanks to Kevin Grant for information about the Thyssens developments.